Prototypes are an essential part of the product design process. A new product is never brought to market without a range of prototypes being created first. The purpose of a prototype varies depending on which stage of the design process falls in. For example; early prototypes are used to test form, size, or even for basic functional testing.

Sketch model prototype design

For cycling hemet design, or saddle design initial form prototypes can be created using a range of methods. 3D printing or hand sculpting are two examples of how to produce quick sketch models of a concept for review. Hand sculpting may have the edge here however, because before any 3D printing can take place, a CAD model will be need to be produced.

Prototype product testing

Prototypes created part way through a design project are often used for more in depth testing. They may be to look closely at how moving parts function. They may be to test how new materials perform under pressure. As an example, if a new core material for cycling helmets is being developed it will need impact testing in extreme temperatures. This is important to see how the properties of the material changes under impact in these extremes conditions.

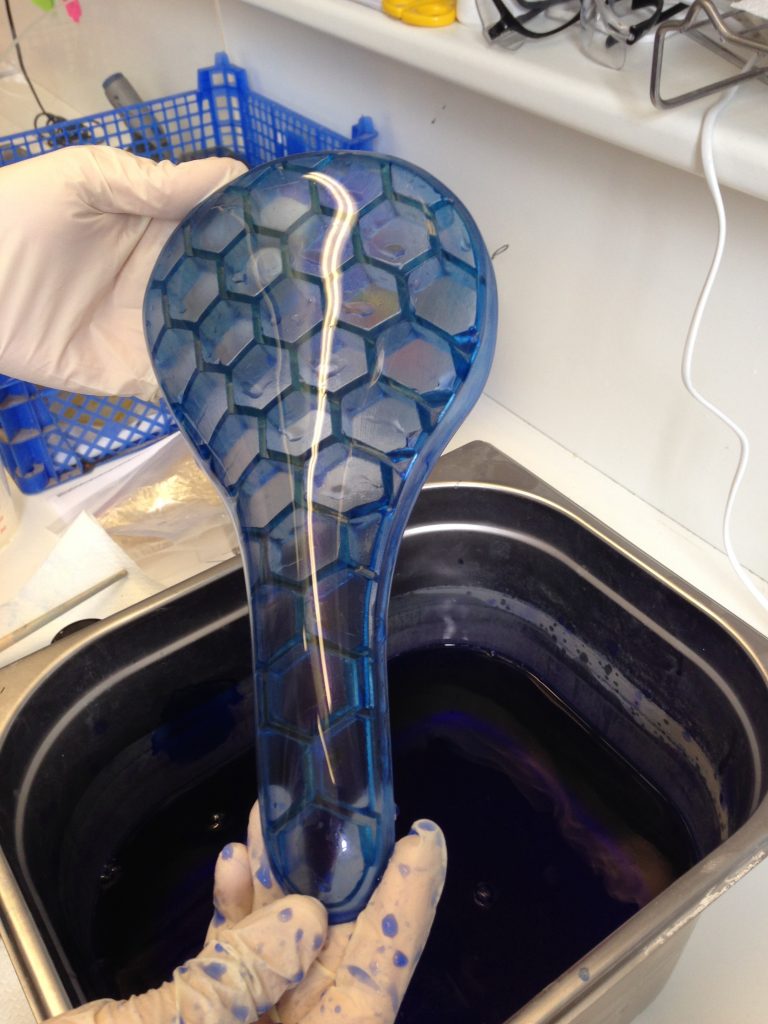

Let’s say a cycling brand is developing a new saddle, let’s say a new saddle design with a pressure relief channel down the middle. This new saddle needs testing before it is released to market to ensure a comfortable ride. This form of testing will usually be done using a factory prototype because of the type of testing required. It can be expensive, especially if there are several iterations needed. Images below are courtesy of Amalgam Modelmaking.

PR & Marketing prototype design

Further down the product development timeline, prototypes are used for things such as dealer book imagery, website images, trade show exhibits and social media posts. A good quality pre-production prototype is generally speaking a lot cheaper to produce than having factory made samples. They are a good way to test the market using focus groups before a new product is launched.

Design for manufacture

Once the prototypes have been tested and the design is fully resolved, a factory can be approached to start tooling for the production pieces. For more information on how to approach a manufacturing partner, please click here.